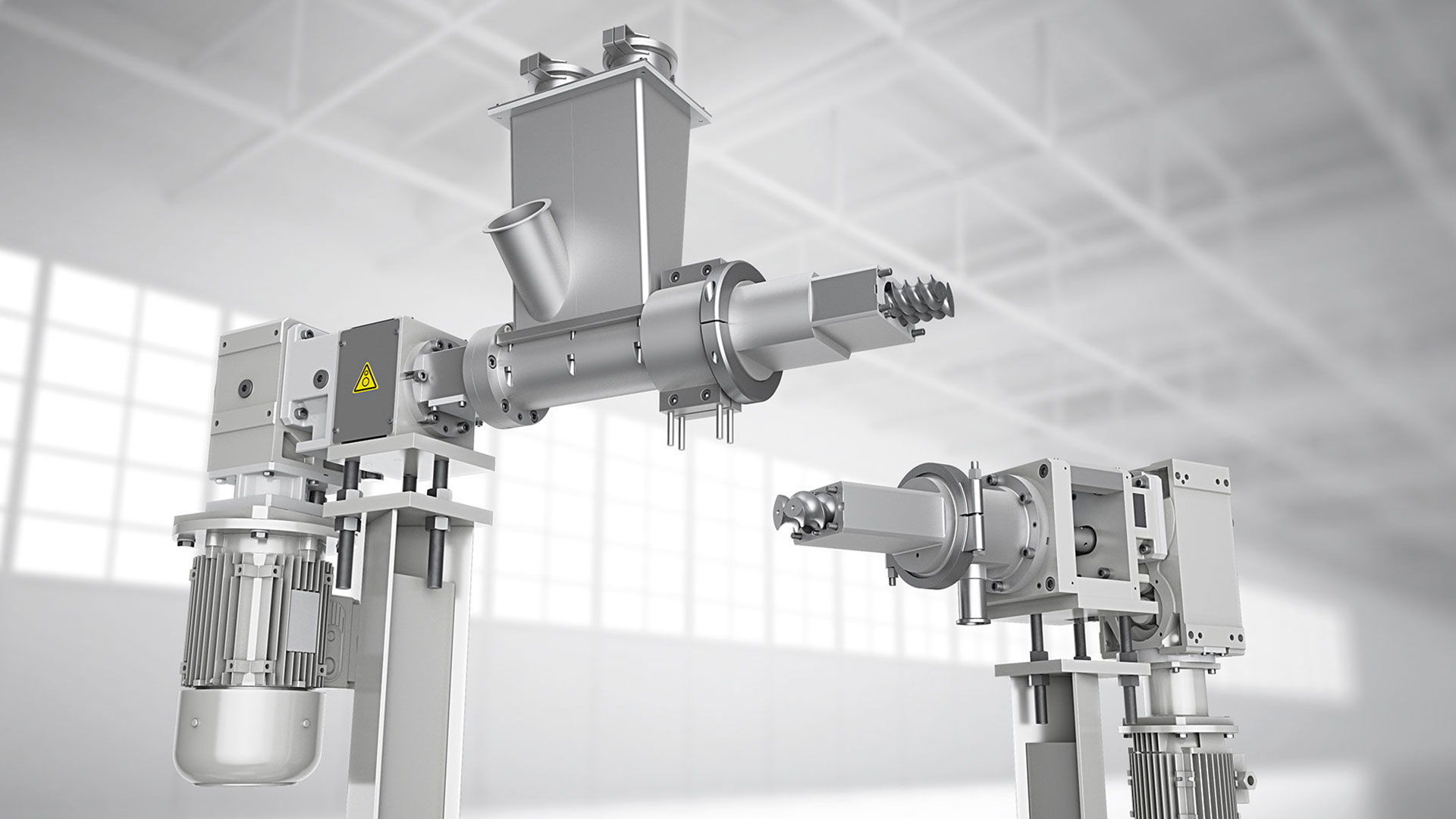

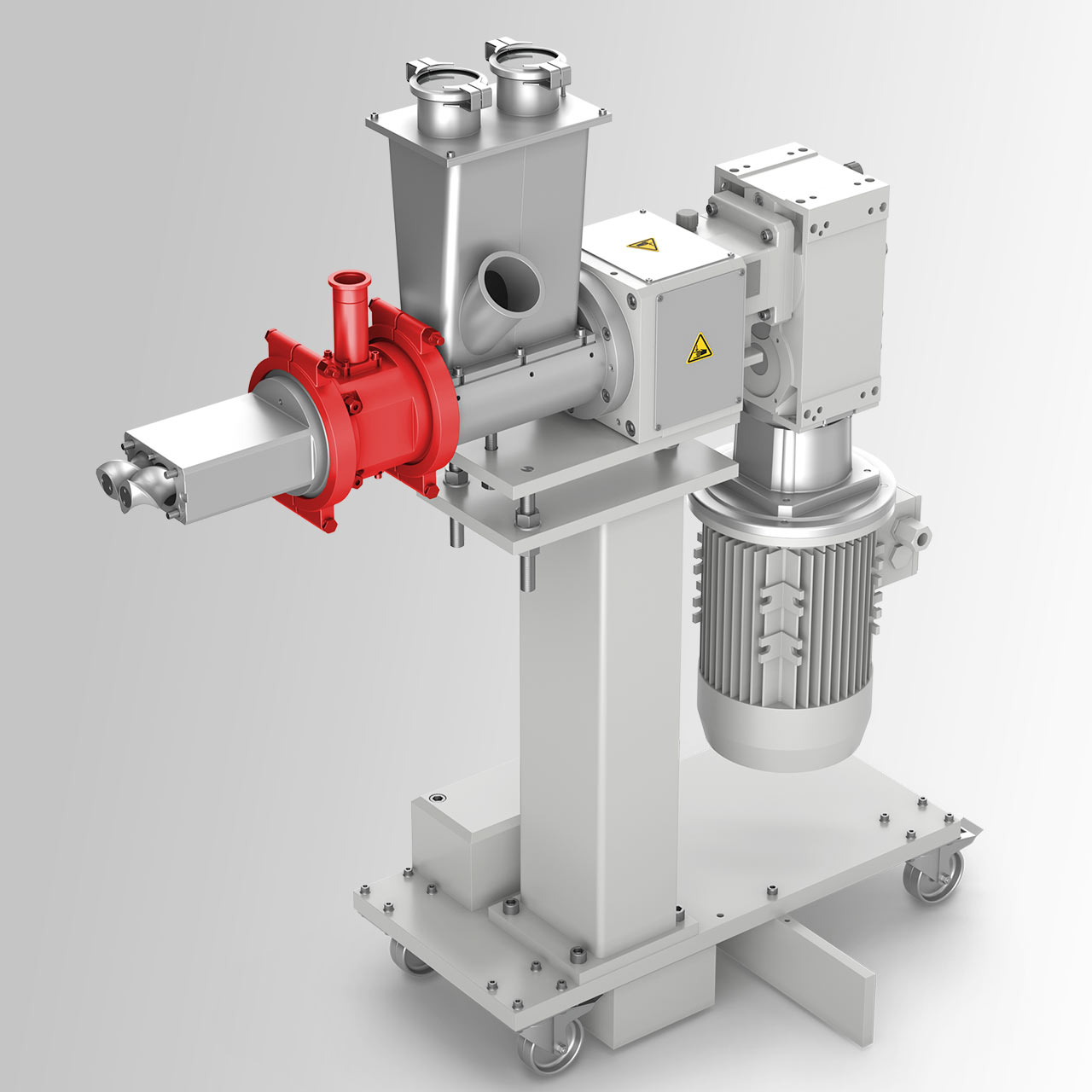

Our High Output Sidefeeder is a customer specific solution we developed that increases your productivity and product quality. The sidefeeder serves to add fillers, reinforcing agents, pigments, flame retardants or further that cannot be taken in at the beginning of the processes due to quality or quantity reasons.

With the new High Output technology, powder can be added to the extruder while simultaneously deaerating.